Anatomy of a Heavy Duty Wrecker

It goes without saying that most people have an understanding of the function of a wrecker, and an overall understanding about the parts needed and the role those parts play in the performance of the wrecker.

However, it’s always interesting to take a look at the individual function of each part in the wrecker anatomy, to understand more in detail how each piece fits into the puzzle.

Additionally, it can be helpful to understand just what can be customized on your wrecker, and what the implications of customizing each part are.

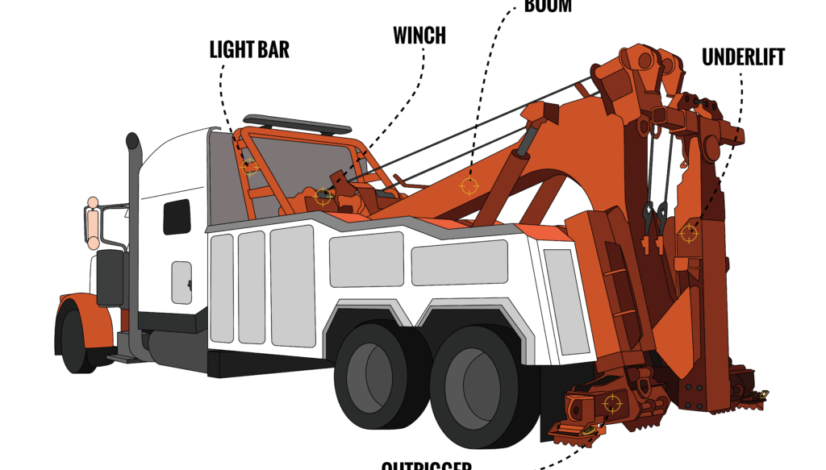

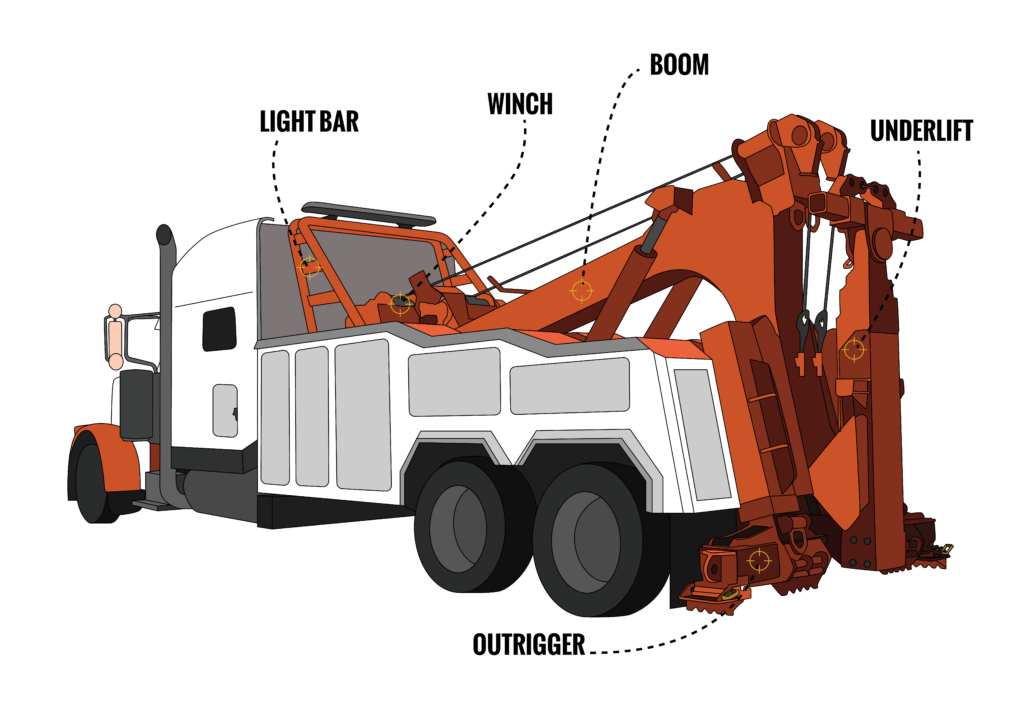

Key Parts of Heavy Duty Wrecker Anatomy

The graphic below displays some of the most important components that make a heavy duty wrecker unique in the towing world:

Each part is further highlighted below to explain the function and purpose.

Boom

A boom, in combination with a winch, is the defining part of a heavy duty tow truck that allows it to recover vehicles from places that are not easily accessible.

Some booms are fixed, but others rotate — creating what is commonly known as a rotator wrecker. These wreckers are used in the most heavy duty applications, such as tractor trailer wrecks.

- Towing Arm: The towing arm mechanism itself can be customized to suit a variety of applications, both in standard, fixed booms and in rotator wreckers.

Tow Sling / Tow Bar

The tow sling is affixed around either an axle on the vehicle or the frame itself, and then the boom and winch lift the vehicle.

The tow bar connects the tow truck and the vehicle being recovered with the use of heavy, rubberized mats. This allows the truck to then be towed on the other axle that is not affixed to the sling.

It is worth noting that the tow sling and tow bar are not ideal recovery methods for every single vehicle. For example, all-wheel-drive vehicles are not ideal due to the ability of the sling to cause problems with the drivetrain. Additionally, the sling can damage the exterior of the vehicle, causing scratches. These considerations are largely dependent on situation, as oftentimes if a vehicle is wrecked — these elements will become less of a concern.

Wheel-Lift

The metal wheel-lift fits under the wheels on either the front or rear of the vehicle. The vehicle is then lifted off of the ground, and it can be towed.

The size and nature of the wrecker will determine the type of wheel-lift that is used. Heavy duty trucks tend to have an underlift (also known as a chassis lift) that lifts the axle or frame of the vehicle, rather than the wheels.

Trucks can be customized and fitted with adapters that allow for a chassis lift when required.

Integrated Wrecker Anatomy

On integrated wreckers, the wheel-lift and boom are combined on one unit, streamlining the tow fleet’s ability to complete many types of jobs and reducing the number of vehicles needed to do so.

Rear Outriggers

Outriggers serve the purpose of helping to cover a greater area, while increasing lift capacity that is achievable by the wrecker. These metal “legs” are also used to help with stabilization during heavy duty recovery jobs.

Depending on your vehicle, these outriggers can be customized in size, shape, and material to make sure they are at peak performance when needed.

Forks and Receivers

These smaller towing accessories are crucial to ensuring jobs go smoothly. The type of fork and receiver needed is largely dependent on your wrecker, and the nature of the jobs you are pursuing.

For most cases, stock forks and receivers fit most trucks and are a great option when investing in towing accessories. However, in unique applications, custom forks and receivers can be created to perfectly fit your needs.|

Light Bar

The inclusion of a light bar on a heavy duty wrecker helps create additional visibility for jobs that are not well-lit, which can have implications on the ease of the job, safety of the operator, and time spent on the job.

Stock tow trucks are often not equipped with ample light to accomplish all of the above.

No Two Heavy Duty Wreckers Are the Same…

… Especially if special care and attention was given to ensure the heavy duty wrecker was custom made for your fleet. All of the components above can be adjusted, customized, and optimized to maximize the performance of your fleet.

If you’re interested in building your own heavy duty custom wrecker, get in touch with the Custom Built team today.