How to Build the Right Custom Tow Truck

All the formulas needed for choosing the right chassis and wheel base for your custom tow truck building needs.

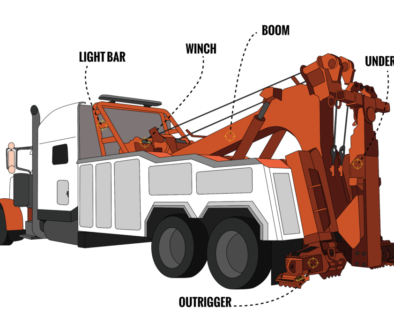

There are many different terms and specifications used when you are building a new wrecker or even when you are looking at a pre-owned wrecker or tow truck. Additionally, it’s important to be familiar with the formulas that determine the ideal build for your tow truck.

This article reviews a few of those and help you decide what is the best combination for your next wrecker or what the capacities of your current unit are.

4 Key Custom Built Tow Truck Terms to Understand:

The following terms are integral in understanding exactly what is factored into the building of your ideal custom tow truck:

- Front Axle weight (FAW) is the actual amount of weight on your front axle when it is being weighed.

- Gross Axle weight rating (GAWR) is the rating the manufacturer has given the axle and its components and should not be exceeded.

- Wheelbase (WB) is the length between the center of the front axle and the center of the rear axles. For a tandem rear axle unit you would measure to the center space between the two axles or wheels, for a tri axle you would measure to the center of the middle axle. Twin steer units are measured between both front axles.

- Overhang is the length from the center of the rear axle or axles to the point on your under lift that you are lifting. i.e. the center of the forks or the center of the tire lift.

Wheelbase and Chassis Requirements for Custom Tow Trucks:

Many customers have different wheelbase and chassis requirements Many times it depends on the roads you travel most often — taking into account the conditions of roads, width of roads, and local requirements from DOT.

A customer in a rural area may require that one of their trucks has a short wheel base in order to use it for recoveries across narrow country roads. Another customer may require a long wheel base for hauling heavy units long distances.

When choosing your chassis or wheelbase you should determine what the truck will be doing the majority of its time and then work with your manufacturer to create the right mix for you.

How to Measure Wheelbase and Other Key Specifications:

Let’s take a look at a couple of examples of how changing the above factors affects the overall build specifications for your wrecker.

Example #1 — The Basics:

A CB50 truck is being built for both towing and recovery. The customer needed to keep the front axle weight while towing, and knew that the best way for him to do that was to add length to his wheel base. Here are the specifications for this truck:

- Front axle Weight (FAW) 14,000 lbs

- Rear axle Weight (RAW) 28,000 lbs

- Gross Vehicle Weight (GVW) 42,000 Lbs

- Wheelbase to center of Tandams 330″

- Overhang 138″

NOTE: To maintain safe steering, braking, and control of your vehicle you should never have less than 50% front axle weight.

Keeping this in mind for the example given, the front axle weight would need to be 1/2 of 14,000 lbs or 7,000 lbs. The formula used to calculate this is as follows:

FAW/2 = Safe Weight X Wheelbase/Overhang= total Capacity

OR

14,000lbs/2 = 7,000lbs X 330″ = 2,310,000 / 138″= 16,739 lbs

Example #2 — Understanding the FAW:

Now let’s look at how much difference FAW makes.

In the next two examples we are only going to change the weight of the front axle. The first will be by adding 2,000 lbs to the total FAW and the second will be removing 2,000 from the total FAW.

16,000lbs/2 = 8,000lbs X330″ = 2,640,000 /138″ = 19,130 lbs

12,000lbs/2 = 6,000lbs X 330″ = 1,980,000 / 138″= 14,34l lbs

As you can see from the numbers above, the actual front axle weight is almost directly transferred to the total lift capacity. When we added 2,000 lbs to the front axle, we gain just over 2,000 lbs total capacity. When we removed the same weight from the front axle, we lost almost that same amount total capacity.

Example #3 — Understanding the Wheelbase:

Now lets see how this translates to wheel base.

In this scenario we will just change the wheel base. We will shorten the wheelbase in 10″ increments to see how the over all total capacity changes.

14,000lbs/2 = 7,000 lbs X 320″ = 2,240,000 /138″= 16,231 lbs

14,000lbs/2 = 7,000 lbs X 310= 2,170,000 / 138″ = 15,724 lbs

When we took away wheelbase in these examples, we only lost about 500lbs of capacity for each 10″ reduction. On this heavy of a unit its not that concerning, but on a lighter unit with less front axle weight it can make a large difference.

Example #4 — Understanding Overhang:

For our final example let’s look at what happens when we change the overhang.

We will add 10″ than 36″ as though the underlift was extended.

14,000lbs/2 = 7,000lbs X 330″ = 2,310,000 / 148″= 15,608 lbs

14,000lbs/2 = 7,000lbs X 330″ = 2,310,000 / 174″= 13,275 lbs

By adding just 10″ of Overhang we lost 1,131 lbs. When we added 36″ we lost 3,464 lbs of total capacity.

Since the overhang works like a giant lever it is almost twice as effective removing FAW as adding wheel base is to gaining FAW!

How to Choose a Chassis:

From everything we just stated, the FAW is very important when choosing your chassis. If you know you are often towing trucks such as loaded Tri Axle Dump trucks, drilling rigs, and front packers — then you will want to consider building with some weight to the front.

How can you do this? Some simple ideas include:

- Placing the Hydraulic tank as far forward as you can on the frame, making the front tool box carry the heaviest items in your truck like chains, forks and snatch blocks.

- Specify that you would like a weight added to the front of the chassis that does not exceed the capacity of the axle.

- Add a side puller. Adding a few thousand pounds just behind the cab could transfer 2/3rds of its weight to the front axle, plus you have a usable tool for side recoveries.

Wheelbase is important as well, but in many cases can only be adjusted when the unit is being built. There are options like adding a Pusher or Tag Axle to your truck that will gain or remove wheel base depending on where its mounted. In some cases, this can also remove some weight from the front axle so be careful how you use this.

NOTE: It can be as effective to decrease your overhang as it is having weighted front axle. As we saw above, just 10 inches of overhang will remove over 1,100 lbs. You are at a large disadvantage if your truck already started out with a large overhang.

Working with a Custom Built Tow Truck Manufacturer:

Once you have decided on the key facets of your new wrecker, it is time for the fun stuff like lights, toolboxes, and gadgets. Designing your new unit should be a fun process for you, and having all the right information will make it easier.

Partner with a tow truck manufacturer who has a team of experts on staff to make the process painless, and even a little fun.

For more information on how Custom Built can help with your next wrecker project, click the link below to talk to an expert and learn more.